At the JEC Composites show, CGTech will demonstrate how advanced programming strategies and simulation can lead to better composite parts.

VCP gives composite part designers complete control over their part. With a wide variety of path laying algorithms, engineers can ensure that they capture the design intent of their composite work piece. Using tools inside of VCP, the part designer or engineer can easily create and experiment with various Automated Fiber Placement (AFP) path options. They can also evaluate the effects of AFP manufacturing on a composite part’s design intent.

VCS gives an entire organization the confidence needed to run composite NC machines correctly the first time. Regardless of the programming system used (VCP or others), users can verify NC code to identify issues, such as: collisions, NC syntax errors, and material placement quality. Because the material is applied to the layup form via NC program instructions in a virtual CNC simulation environment, the simulated part can be measured and inspected to ensure the NC program follows manufacturing constraints.

Both VCP & VCS can be used to program and simulate any number of machines. Both programs include support for probing, knife trimming paths, laser projection, Automated Fibre Placement (AFP), and Automated Tape Laying (ATL) machines.

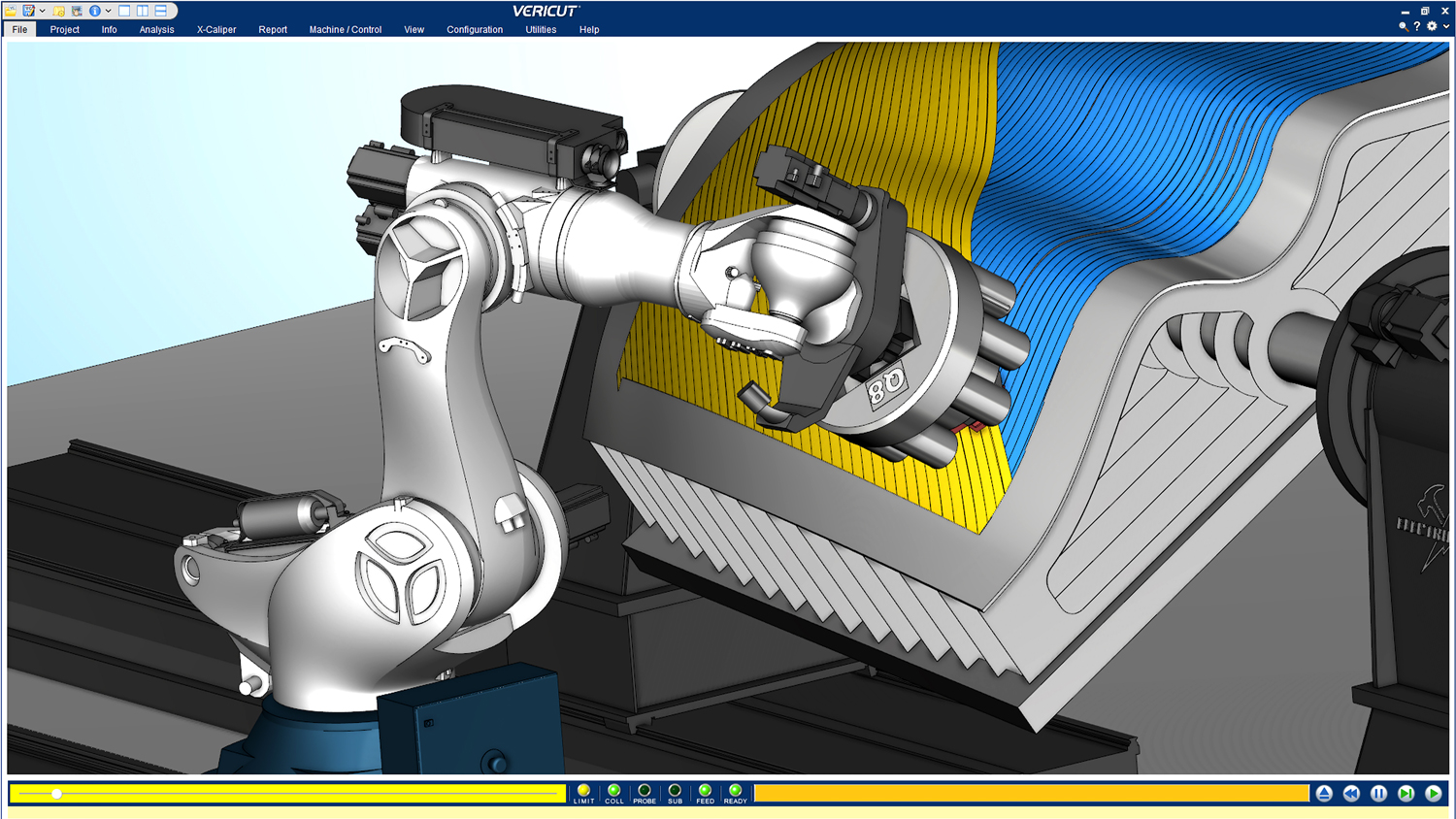

For manufacturers applying robotic automation to cutting and trimming, drilling and fastening, as well as fiber placement, VERICUT simulates 6-axis articulated-arm robot motion from leading robot machine builders including Fanuc, KUKA, ABB, Kawasaki, Motorman and others. VERICUT also supports robots that have additional ‘external’ axes such as those mounted on a linear rail.

“CGTech has assembled an international panel of composite manufacturing experts to discuss the challenges facing the industry today and present their experiences across multiple industries,” says Mark Forth, Global Business Development Manager. “Attendees can glean practical knowledge and even benchmark their own progress and preparation for the predicted growth of the high-performance lightweight materials sector.”